Genelec 8050B PM Studio Monitor Genelec

$ 1.895,00 $ 473,75

Genelec 8050B PM

The Genelec 8050B is an 8″, 170W bi-amplified active monitor for large facilities featuring proprietary Genelec technology, including the Directivity Control Waveguide, Minimum Diffraction Enclosure, and the power-saving auto-shutoff of Intelligent Signal Sensing circuitry – Producer Grey finish, magnetically shielded (PM)

With a pair of Genelec 8050Bs, you only have to invest in nearfield studio monitors once – no wishing you got the bigger woofer for more bass extension and wider frequency range; no longing for more power to fill up the room when the time comes to crank the mix for clients (or friends); and no second-guessing if you bought the right monitors at all. A truly professional tool, the 8050B offers a class-leading balance of expansive dynamic range, extraordinary SPL output, extremely detailed transparent performance. Featuring the sleek good looks and practical functionality of the all-aluminum Minimum Diffraction Enclosure (MDE), precise on- and off-axis frequency response of the Directivity Control Waveguide (DCW), and broad low-frequencies characteristics of the flow-optimized internal curved reflex tube, the Genelec 8050B is the apex of form and functionality. And if you are concerned with investment, the 8050B saves your studio money by automatically entering a power-saving standby mode, courtesy of Genelec’s Intelligent Signal Sensing (ISS) circuitry.

Genelec 8050B PM – Just the Facts :

- Directivity Control Waveguide (DCW) technology for accurate on- and off-axis response

- Minimum Diffraction Enclosure (MDE) eliminates unwanted cabinet reflections

- Quiet reflex port design with high air flow

- Room-response EQ compensation

- Highly efficient class D amplifiers optimized for Genelec drivers

- Active crossovers

- Driver-protection circuitry

- Intelligent Signal Sensing (ISS) power-saving technology

- Iso-Pod decoupling and speaker orientation stand

- Versatile mounting options

- Producer Grey finish (P)

- Magnetically shielded (M)

Genelec 8050B PM – Behind the Grille

Directivity Control Waveguide (DCW) Technology

Genelec’s Directivity Control Waveguide shapes the emitted wavefront of direct radiating multi-way monitors in a way that allows predictable tailoring of the speaker’s dispersion pattern. DCW technology also minimizes early reflections, providing a wide, controlled listening area with accurate sound reproduction both on- and off-axis.

Another advantage of minimized early reflections and controlled constant directivity is that the frequency balance of the room’s reverberation field is essentially the same as the direct field from the monitors. As a result, the monitor’s performance is less affected by room acoustic characteristics.

The consistent off-axis frequency response of the waveguide enables engineers to move in and out of the sweet spot without losing perspective while working room.

DCW technology key benefits:

- Flat on- and off-axis response for wider usable listening area

- Increased direct-to-reflected sound ratio for reduced control room coloration

- Improved stereo and soundstage imaging

- Increased drive unit sensitivity up to 6dB

- Increased system maximum sound pressure level capacity

- Decreased drive unit distortion

- Reduced cabinet edge diffraction

- Reduced complete system distortion

Minimum Diffraction Enclosure (MDE™) Technology

Genelec’s highly innovative aluminum enclosure (MDE) improves the linearity of the frequency range and power response of free-standing monitors via rounded edges and gently curved front and sides optimized to match the acoustic properties of the drivers. In addition to achieving a remarkably flat frequency response, minimizing cabinet diffraction yields superb sound stage imaging.

Directivity is further improved by the waveguide being integrated into the MDE enclosure. Since the low-frequency limit for constant directivity is determined by the size of the waveguide, the larger the surface the better the control. Highly directional off-axis radiation yields a consistent listening window, which is critically important in multichannel monitoring. Controlled directivity also reduces possible first-order reflections on surfaces near the loudspeaker, such as walls, floors, ceilings, and studio furniture, which contributes to consistent audio reproduction in various acoustical environments.

High air-flow bass reflex port design

There are three methods to handle bass frequencies in small monitors, infinite baffle, or sealed cabinet, ported reflex, and transmission line (passive radiator designs are a subset of ported reflex speakers). Genelec’s choice for vented, or reflex, enclosures dates back to the first Genelec product in 1978. Since then Genelec has refined and improved their designs to increase low-frequency extension and sound pressure level capability to provide outstanding bass articulation and definition.

The downside of ported designs is that turbulence in the ports due to extreme air pressure from the driver excursions can cause chuffing noise in the ports, and/or interfere with frequencies higher up in the spectrum. To minimize air speed and turbulence, the cross-sectional area of the vent should be large. This, in turn, means that the vent tube has to be long, which presents quite a design challenge. Genelec’s solution is a long, curved tube that maximizes airflow so deep bass can be reproduced without compression. The reflex tube terminates with a wide flare located on the rear of the enclosure minimizing port noise and providing excellent bass articulation.

The curvature of the tube has also been carefully designed to minimize any audible noise, compression, or distortion. The inner end of the tube has proper resistive termination to minimize audible chuffing noise and air turbulence. Proper reflex port design allows also to significantly reduce the woofer’s displacement, improving the linear low-frequency output capacity.

PAD Pro tech note: For small cabinets to handle bass frequencies lower than the laws of physics would allow, the ported or reflex is the easiest design from a manufacturing standpoint to achieve a deep bass response. It takes advantage of the cabinet’s resonance and in essence feeds sound coming from the rear of the speaker through a tube connected to the back of the cabinet into ports, which are usually on the front panel. The length and diameter of the tube are precisely calculated for the desired low-frequency response. The trick is to make sure the sound coming from the port is in phase with the speaker, which reinforces the low frequencies of the monitor. It’s important to note that while this technique does provide a better bass response in small cabinets, it’s primarily a psychoacoustic effect. The addition of a subwoofer enables smaller drivers to handle midrange frequencies while bass frequencies are directed to a larger dedicated bass driver.

Intelligent Signal Sensing function

Genelec’s Intelligent Signal Sensing (ISS) is a power-saving feature that prolongs the service life of the monitor. ISS reduces power consumption to less than 0.5 watts by automatically switching the active monitor to standby when no audio signal has been detected for some time. When playback begins, the mode indicator light on the loudspeaker lights up and the playback resumes after a slight delay (<2 seconds).

Protection circuitry

The protection circuitry prevents driver failure by detecting signal levels and responding accordingly. In the case of sudden peaks or levels that are too high for long periods, the protection circuitry reduces signal level automatically. This feature does not affect the sound quality in any way when working within the specifications of the loudspeaker, but only prevents inappropriate input signals from breaking the loudspeaker.

Protection circuitry features and benefits:

- Reduces the output level when required (e.g. when driver voice coil temperature reaches the safe limit), which highly improves system reliability

- Appropriate protection circuitry design for each loudspeaker and subwoofer maximizes system output level

Room compensation controls

Each room changes the monitor’s response in a unique way, e.g. reflective vs. damped rooms, or placement against a wall vs. on a stand away from the walls. All Genelec loudspeaker systems feature room response adjustments to compensate for the room influences and retrieve a flat frequency response at the listening position. Frequency response can be adjusted to match the acoustic environment by setting the tone control switches on the rear panel of all Genelec monitors.

Optimized amplifiers with active crossover

In a typical 2-way loudspeaker system, the active crossover needs two power amplifiers; one for the woofer and one for the tweeter. Electronic crossovers split the audio signal into separate frequency bands that can be separately routed to individual power amplifiers optimized for the frequency band of their respective transducers.

The power amplifiers are connected directly to the drivers of an active loudspeaker, resulting in the power amplifier’s load becoming much simpler. Each driver-specific power amplifier has only a limited frequency range to amplify (the power amplifier is placed after the active crossover), which adds to the ease of design.

The active design principle offers multiple benefits:

- The power amplifiers are directly connected to the speaker drivers, maximizing the control exerted by the power amplifier’s damping on the driver’s voice coil, reducing the consequences of dynamic changes in the driver electrical characteristics. This may improve the transient response of the system

- There is a reduction in the power amplifier output requirement. With no energy lost in the passive crossover filter components, the amplifier power output requirements are reduced considerably (by up to 1/2 in some cases) without any reduction in the acoustic power output of the loudspeaker system. This can reduce costs and increase audio quality and system reliability

- No loss between amplifier and driver units results in maximum acoustic efficiency

- Active technology can achieve superior sound output vs. size vs. low-frequency cut-off performance

- All loudspeakers are delivered as a factory aligned system (amplifiers, crossover electronics, and enclosure-driver systems)

Iso-Pod stand

Often workstation furniture has equipment racks whose top surfaces double as speaker stands. While this may be a convenient option, placing speakers on wooden surfaces or console meter bridges has side effects detrimental to accurate and effective monitoring. In such a scenario, aiming the loudspeaker axis towards the listener rarely occurs, and sympathetic vibrations (which are not very sympathetic to bass) propagate from the loudspeaker to the surface. Also, first-order reflections on the surface cause comb filtering and subsequently ripples in the frequency response.

To solve these very common problems, Genelec designed the Iso-Pod Isolation Positioner/De-coupler. Made from special lossy rubber-like material to de-couple the speaker from a surface, it has four shallow feet and is firmly attached to the enclosure so that it can be slid along the curved bottom or side surface to allow for a ±15° tilt of the loudspeaker. The loudspeaker’s acoustical axis can then be pointed precisely towards the listener. The vibration isolation and damping properties reduce midrange coloration caused by unwanted vibration transmitted to supporting surfaces.

Versatile mounting options

On the base of the 8050B is a 3/8″ UNC threaded hole which can accommodate a standard microphone stand. On the rear there are two M6x10 mm threaded holes for an Omni-mount size 20.5 bracket.

The Genelec 8050B is most at home in large facilities, world-renowned mastering suites, and broadcasting hubs. For more information, call or chat online with your PAD Studio Specialist today.

Specifications

- Lower cut-off frequency, –3dB: ≤35Hz

- Upper cut-off frequency, –3dB: ≥21kHz

- Accuracy of frequency response: 38Hz – 20kHz (± 2.0dB)

- Maximum short term sine wave acoustic output on axis in half space, averaged from 100Hz to 3kHz: @ 1 m ≥110dB SPL; @ 0.5 m: 116dB SPL

- Maximum long-term RMS acoustic output in same conditions with IEC weighted noise (limited by driver unit protection circuit): @ 1 m ≥101dB

- Maximum peak acoustic output per pair @ 1 m distance with music material: >120dB

- Self-generated noise level in free field @ 1 m on axis: ≤10dB (A-weighted)

- Harmonic distortion at 85dB SPL @ 1 m on axis: Freq: 50-100Hz < 2%; >100Hz < 0.5%

- Bass driver: 8″ (205 mm) cone

- Treble 3/4″ (19 mm) metal dome

- Magnetically shielded (M)

Crossover Section

- Connector: Input: XLR female, balanced 10k ohm, pin 1 gnd, pin 2 +, pin 3 –

- Input level for 100dB SPL output at 1 m: adjustable from +6dBu to -6dBu

- Input sensitivity control range relative to max output: -12dB (constantly variable)

- Crossover frequency, Bass/Treble: 1.8kHz

- Treble Tilt control operating range in 2dB steps: +2 to –4dB and mute @ 15kHz

- Bass Roll-Off control in 2dB steps: 0 to –6dB step @ 35Hz

- Bass Tilt control operating range in –2 dB steps: 0 to –6dB @ 100Hz and mute

The ‘CAL’ position is with all tone controls set to “off” and the input sensitivity control to maximum (fully clockwise)

Amplifier Section

- Bass amplifier output power: 150W

- Treble amplifier output power: 120W

(Long term output power is limited by driver unit protection circuitry)

Amplifier system distortion at nominal output:

- THD: ≤0.05%

- SMPTE-IM: ≤0.05%

- CCIF-IM: ≤0.05%

- DIM 100: ≤0.05%

Signal-to-noise ratio, full output:

- Bass: ≥ 100dB

- Treble: ≥100dB

- Mains voltage: 100-240 VAC 50-60Hz

- Voltage operating range: ±10 %

Power consumption:

- Idle: 10W

- Standby in ISS mode <0.5W;

- Full output: 170W

Physical

- Finish: Producer Grey (P)

Dimensions:

- Weight without IsoPod stand: 17-1/16″ (433 mm)

- Height with IsoPod stand: 17-13/16″ (452 mm)

- Width 11-1/4″ (286 mm)

- Depth: 10-15/16″ (278 mm)

Weight:

- 7 lb. (14.4 kg)

| Colour | Producer Finish, White Finish (Special Order) |

|---|---|

| Configuration | Single, Pair |

Prompt Delivery and Professional Packaging

Our long-standing partnership with UPS FedEx DHL and other global carriers lets us offer a range of shipping services. Our warehouse staff is extremely skilled and will package your items according to our precise and exact specifications. Your goods will undergo an extensive inspection and be safely packaged prior to being sent out. Each day, we ship to thousands of customers in many countries. The fact that we are committed to becoming the biggest online retailer in the World is clear. These warehouses are in Europe in the same way as they are in USA.

Note: Orders that include more than one item are assigned a processing period depending on the item.

Before shipping, we will inspect thoroughly the items you have ordered. Most orders are shipped within 48 hours. Expected delivery time is between 3-7 days.

Returns

Stock is dynamic. It's not entirely managed by us since we are involved with multiple entities, including the factory and the storage. The actual stock can change at any moment. It is possible that your order may be out of stock once the order has been placed.

Our policy lasts for 30 days. We cannot exchange or refund your order if it has been 30 days from the date of purchase.

For your item to be returned it must be in its original packaging, unopened and in the condition you received it. The item must be in its original packaging.

Related products

Headphones

Accessories

Mic Preamp

500 Series

Accessories

Monitor

500 Series

Monitor Systems

Microphones

Equalizers

Subwoofer

Recording Equipments

Mic Preamp

Microphones

Subwoofer

Microphones

Microphones

Recording Equipments

Accessories

Recording Equipments

Monitor Systems

Monitor Systems

Microphones

Monitor Systems

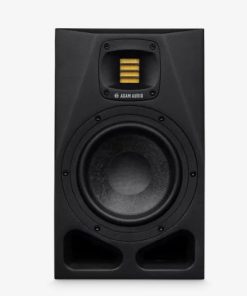

Monitor

Recording Equipments

Monitor

Monitor Systems

Microphones