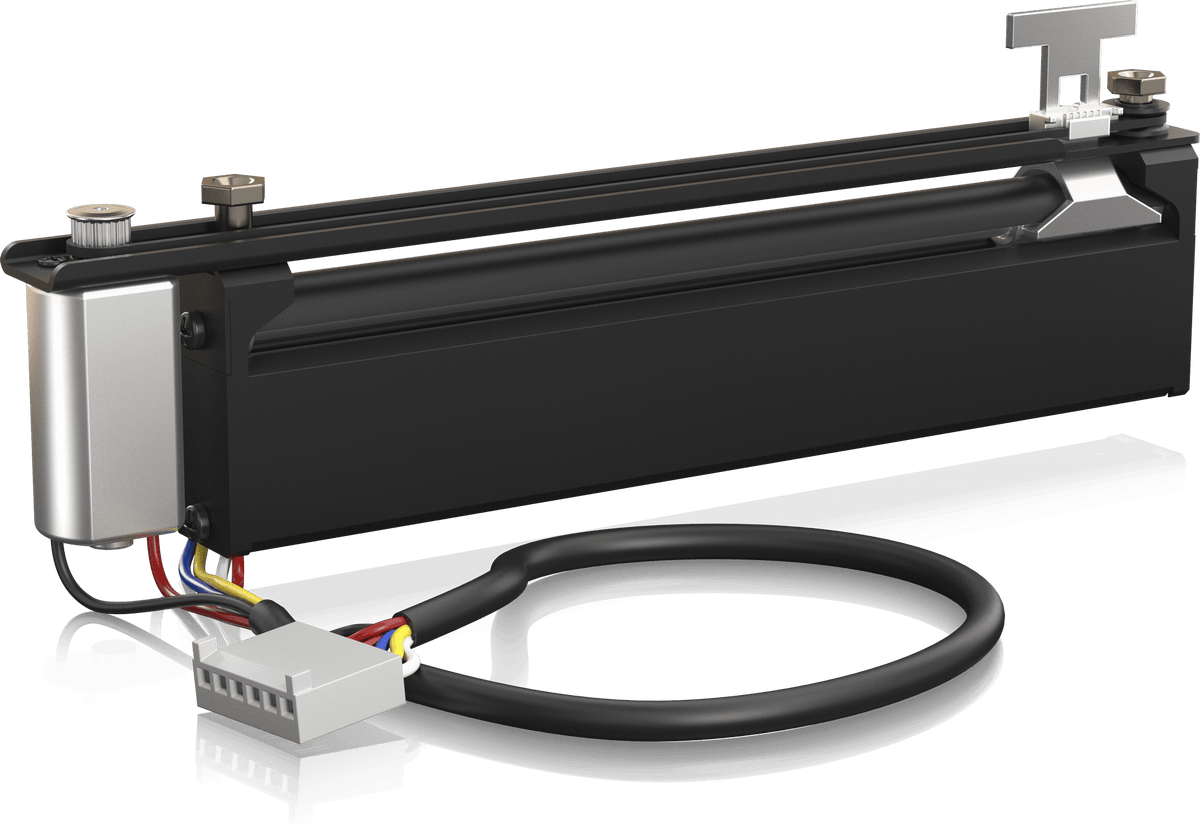

MIDAS PRO FADER (200 MM) Midas

$ 219,00 $ 87,60

Set of 5 High-Endurance, Touch-Sensitive 100 mm Motorised Faders (200 mm Cable)

Not satisfied with the existing motorised fader choices in the marketplace, Midas created the PRO FADER, rated for up to a million cycles – three times that of other leading manufacturers – and providing high linearity, robustness, and smooth feel during operation. This decision yielded many other benefits, including total quality control over the manufacturing process and lower costs that could be passed on to customers.

As a digital console manufacturer, Midas has a perspective on the actual application of motor faders that a component manufacturer would not have. The multi-disciplinary development project combined mechanical design, electronic hardware and software optimisation with a rigorous testing programme and an investment in material science to produce the best possible performance in actual operation in Midas PRO Series consoles. Semi-precious metals are used for the wiper fingers for their hard-wearing properties, and precision resistive tracks were created that off er highly linear positional accuracy, coupled with long-term durability and even response in use.

PRO FADER (200 mm) features a high precision 100 mm travel track with a 10 kΩ linear law, ideally suited to servo control applications. The integrated touch sensing track and conductive T-Bar allow both the implementation of automatic channel selection in software, as well as detection of when the fader is being held so that the motor is not driven. PRO FADER (200 mm) is designed to be mounted to console fascia panels via its two M3 threaded pillars which are on 120 mm mounting centres. A 200 mm long cable is provided which includes connections for the 10 kΩ resistive track, the touch sensing track and the motor.

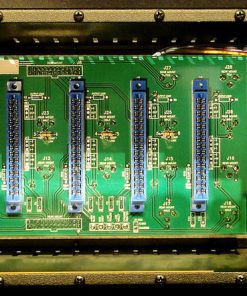

PRO FADER (200 mm) is supplied as a set of five faders and is suitable for use in the input and output fader bays in all Midas PRO Series digital consoles and control centres. PRO FADER (200 mm) is also a replacement for industry standard parts such as Penny+Giles PGFM3200, Alps K-Fader and other similar 100 mm motorised faders.

Architecture & Engineering Specifications

- The motorised fader shall be intended for use on digital audio mixing consoles and control centres as part of a linear position-sensing servo circuit.

- The motorised fader shall have an operational lifetime of up to 1 million cycles.

- The motorised fader shall have a 10 kΩ ± 20% linear law track with ± 2% linearity.

- The motorised fader shall have 100 mm travel.

- The motorised fader shall use wiper fingers manufactured from Palladium Silver-Copper alloy.

- The motorised fader shall have a touch sensing track which is connected to a conductive T-Bar fixing via a set of wiper fingers.

- The motorised fader shall use a Mabuchi FF-050SB-09250 motor.

- The motorised fader shall have a cable loom of nominal length 200 mm, terminating in a 6-way Molex 22-01-2065 connector shell fitted with 08-50-0031 crimps.

- The motorised fader shall have overall dimensions 150 mm length x 13 mm width x 47 mm high (5.9″ x 0.5″ x 1.9″).

- The motorised fader shall have M3 threaded pillar fixings on 120.0 mm (4.7″) fixing centres.

- The motorised fader shall be the Midas PRO FADER (200 mm) and no other alternative shall be acceptable.

| Title | Default |

|---|

Prompt Delivery and Professional Packaging

Our long-standing partnership with UPS FedEx DHL and other global carriers lets us offer a range of shipping services. Our warehouse staff is extremely skilled and will package your items according to our precise and exact specifications. Your goods will undergo an extensive inspection and be safely packaged prior to being sent out. Each day, we ship to thousands of customers in many countries. The fact that we are committed to becoming the biggest online retailer in the World is clear. These warehouses are in Europe in the same way as they are in USA.

Note: Orders that include more than one item are assigned a processing period depending on the item.

Before shipping, we will inspect thoroughly the items you have ordered. Most orders are shipped within 48 hours. Expected delivery time is between 3-7 days.

Returns

Stock is dynamic. It's not entirely managed by us since we are involved with multiple entities, including the factory and the storage. The actual stock can change at any moment. It is possible that your order may be out of stock once the order has been placed.

Our policy lasts for 30 days. We cannot exchange or refund your order if it has been 30 days from the date of purchase.

For your item to be returned it must be in its original packaging, unopened and in the condition you received it. The item must be in its original packaging.

Related products

Accessories

Avid Avid Advantage, Isis 5500 64Tb System Primary Engine, Expertplus Hardware Coverage Avid

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories

Accessories